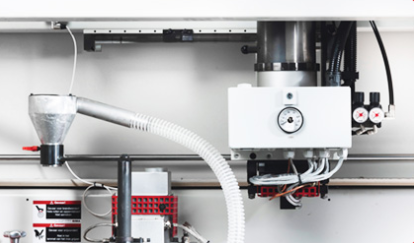

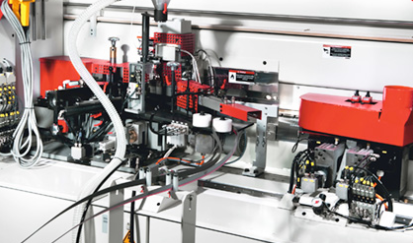

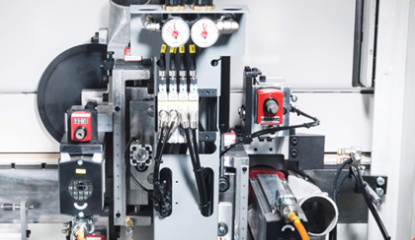

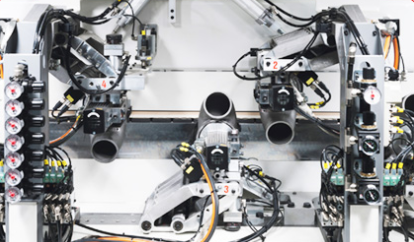

Any inexperienced user who values quality, processing performance and ease of use will find an optimal solution in the Novimat Compact L12. This edgebanding machine handles all aspects of edge processing, offering a highly professional approach to industrial edgebanding. Coiled materials and lippings can be applied with glues such as EVA or PUR. The Compact L12 edgebanding machine fully meets the demands of edge processing at the initial industrial level.

Woodworking manufacturers want edgebanding machines with three primary features: highest-quality edge processing, minimum floor space requirements and lower price. The Novimat Compact L12 edgebanding machine offers all three. All working units of this machine have optimal motor power, ensuring high availability with excellent repeatability and long-term use.

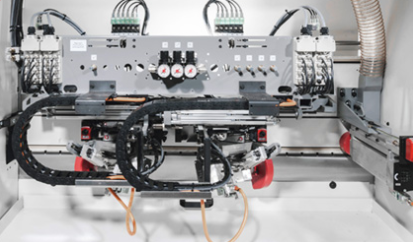

By automating essential functions, the Novimat Compact L12 can process all pending tasks and edging tapes. Control of the machine is through a panel with a large touch screen by which all inputs and checks are accomplished. The operator panel houses all machine and unit controls, ensuring a perfect flow of information between the operator and the machine.

© 2024 IMA Schelling GroupIMA Schelling Group. All Rights Reserved.

Site Designed By:

Gotham Industrial Marketing

Gotham Industrial Marketing

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |