When a machine goes down, it negatively affects production, time, and money. Engage our service team for rapid repairs of:

All repairs are completed right here in the U.S. by factory-trained technicians.

IMA offers expert glue pot repair and rebuild services to keep your IMA edgebander running at an optimal level. Our comprehensive program uses OEM replacement parts and we completely dismantle, clean and coat surfaces required for proper operation. Trust IMA to repair and/or rebuild your edgebander’s glue pot with top-quality parts, service and turnaround time.

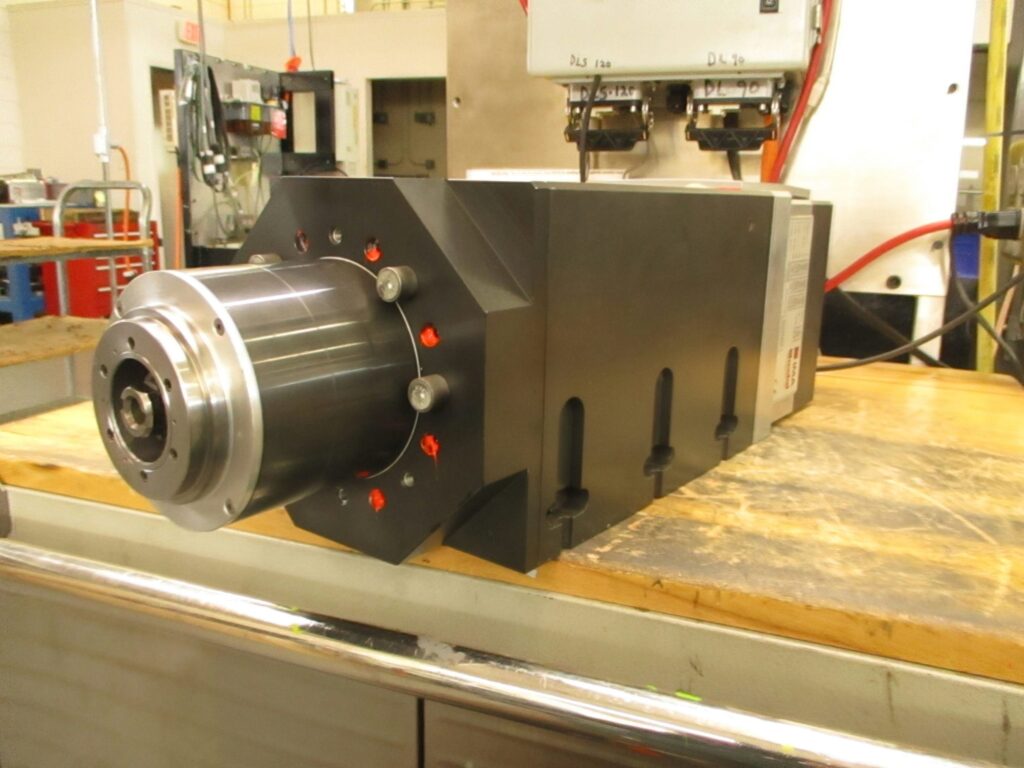

When bearings begin to wear and fail, noise and excessive heat are evident. Another sign is poor finish quality of workpieces. We use IMA original factory parts to rebuild these valuable systems completely. This includes vibration testing of your unit, disassembly, cleaning of all components, testing of shaft balance, new high-precision bearings and seals. Lastly, a run-in test with vibration analysis ensures it runs out of the box. We repair milling spindles used on IMA BIMA CNC machines, Priess, and Horstmann BAT SAX machines and other makes and models.

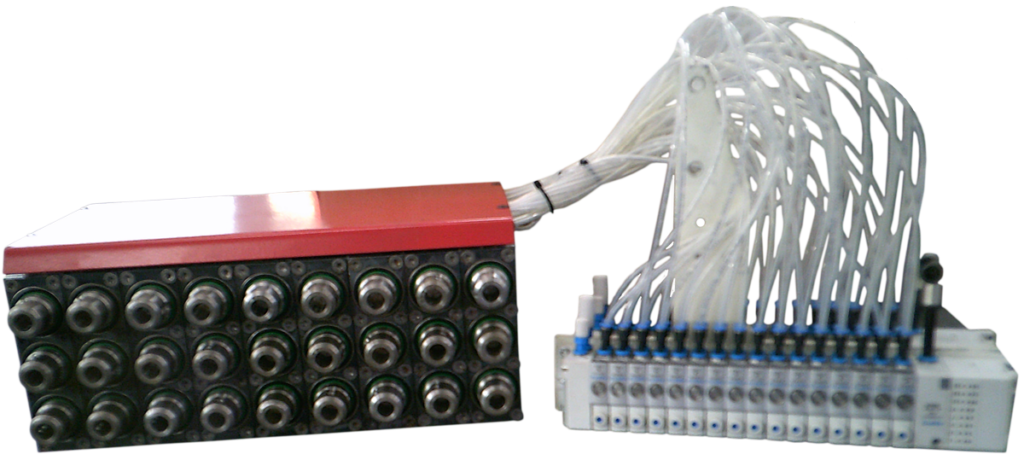

All U.S. drill block repairs are comprehensive, utilizing Schelling factory parts. Our repair process includes replacing O-rings and seals to maximize delivered air pressure in each spindle. Bearings are replaced to ensure smooth operation out of the box. All units are connected to air supply and run at operating speed to monitor temperature and overall efficiency. We effectively repair drill blocks used on IMA BIMA CNC Machines, Priess and Horstmann BAT SAX Machines and IMA IMAGIC Drilling Machines.

Arbor integrity is just as crucial as the tooling in a cutting application. If cut quality is deficient, bearing wear in the saw arbor is the likely culprit. IMA Schelling provides quick-turn repair in the U.S. for significant time and cost savings.

Our arbor repair improves the rotating assembly by precision measuring the bearing housing bore, identifying the intended operating RPM and load, and then specifying the optimal bearing arrangement for the application. Inner flanges are enhanced via face grinding. The saw blade body mounts against this flange, and zero runout is commonly achieved. The result of repaired arbors is exceptional cut quality and optimal levels of service for years.

For cost-effective repairs of Lenze, KEB, Dunkermotoren, WEG, Siemens motors, and servomotors trust the IMA Schelling service team. Every motor repaired is tested on state-of-the-art equipment, disassembled in a clean room, re-assembled with worn parts replaced and finally tested to ensure like-new operability. All servomotors are rebuilt and tested using the latest hardware and software techniques.

Sometimes it makes more sense to repair than replace. We analyze all connections, cooling fans, electrolytic capacitors, power semiconductors and circuit boards. Components found in less than optimal condition are replaced and tested and ready to roll when you power up! Depend on IMA Schelling Group’s Service team for reliable repairs of Lenze, KEB, Beckhoff Variable Frequency Drives.

Prevalent in today’s automated manufacturing operations, Programmable Logic Controls (PLC) and HMI (Human Machine Interface) panels are vital to uptime. Our service department specializes in the repair of PLC’s and HMI’s for Siemens, Pilz, and Beckhoff.

We repair the following PLC’s:

Our experienced team has been intensively trained in repairing Siemens, Pilz, and Beckhoff units to ensure the highest quality repairs. We test digital inputs for threshold (on/off) voltage, and all digital outputs are load tested to evaluate the rated current for each output. Analog inputs and outputs are tested to the manufacturer’s specifications for proper calibration to ensure critical PLC applications perform like new.

We repair the following HMI’s:

Our HMI repair service includes the replacement of broken or failed LCD screens, damaged or broken touch screens and overlays, backlights, and more. Typically, these displays are brighter LCDs.